Safe Robot Applications and Cobots

Tabbed contents

Expertise

Safety first – robots are no exception. To protect people working with machines and robots, comprehensive standards and guidelines have been developed over the years. Consequently, the number of work accidents is going down year after year and innovative applications in the public sector are emerging. However, the sometimes highly restrictive regulations and confusingly large number of specifications make it difficult for users and integrators of robot systems to keep track. In practice, this leads to costly planning errors, with the result that planned cobot applications, for example, are ultimately not certifiable. It is not uncommon for these errors to become apparent very late on in the project when investments in the robot have already been made. Either a fence has to be put around it or the concept cannot be implemented at all.

You can avoid such disappointments by working with us. Thanks to our decades of experience, we know all about the stumbling blocks associated with certification procedures. Through our involvement in international standardization bodies such as ISO, you benefit from our knowledge about the development of future standards. We are also researching into new safety methods that use artificial intelligence and digitization, for example, allowing cobots to be operated with cost-effective cycle times and fenceless.

By collaborating with IPA, you avoid having to make expensive modifications to your robot safety concept at a later stage. With this in mind, we offer different cooperation formats, ranging from initial consulting and practical safety tests on robot applications right through to support with CE marking, benefiting you according to the phase of your project and your level of knowledge. In line with current standards, we develop suitable safety concepts for industrial and service robots, for cobots and HRC applications, for mobile robots with and without manipulators, as well as for everything else you might want to implement as part of an automation solution.

You can also take advantage of our range of software and hardware tools which, among other things, provide automated support and assistance in identifying hazards and select measures to minimize risks. In the future, a new toolchain that is under development will accelerate the risk assessment process for robot systems in compliance with the machinery directive. Last but not least, you are more than welcome to join us for a glimpse into the future of safety. A current focus of our research work is on innovative safety concepts beyond established technologies.

Our Services

Project videos

Privacy warning

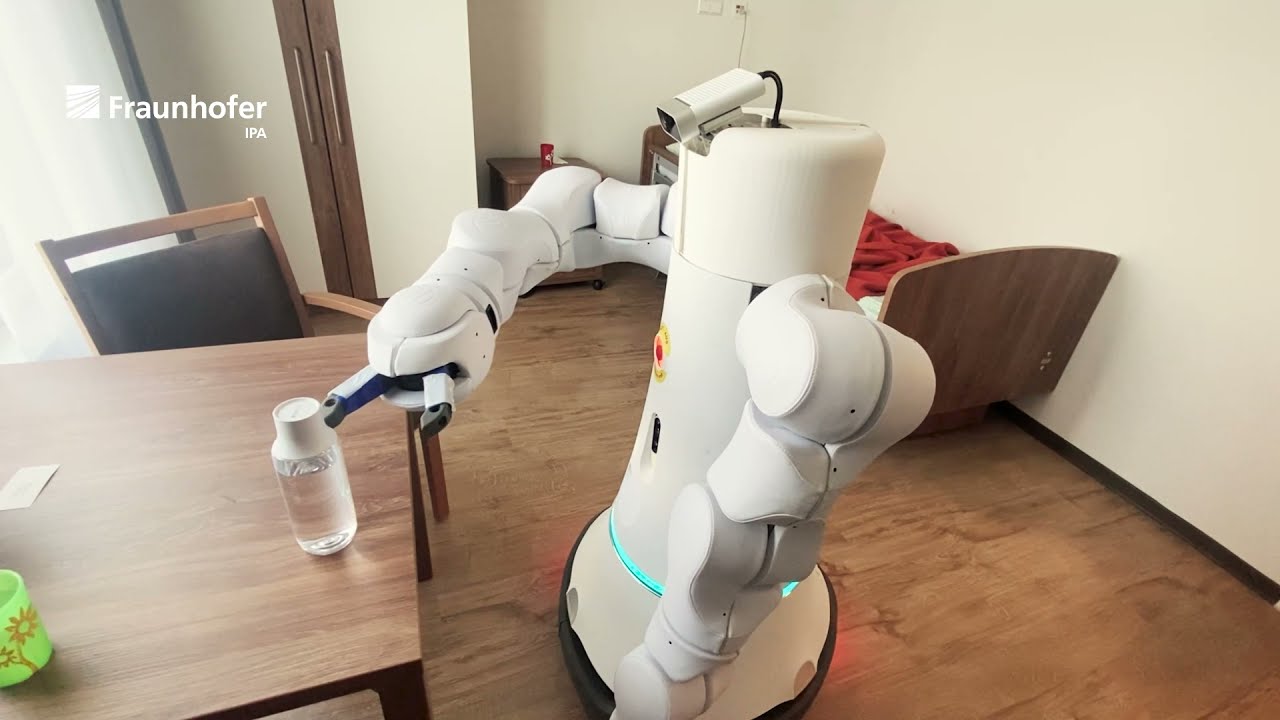

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyCare-O-bot 4 supports nursing staff in retirement homes by replacing beverage bottles