Fraunhofer IPA plans project center in Shanghai

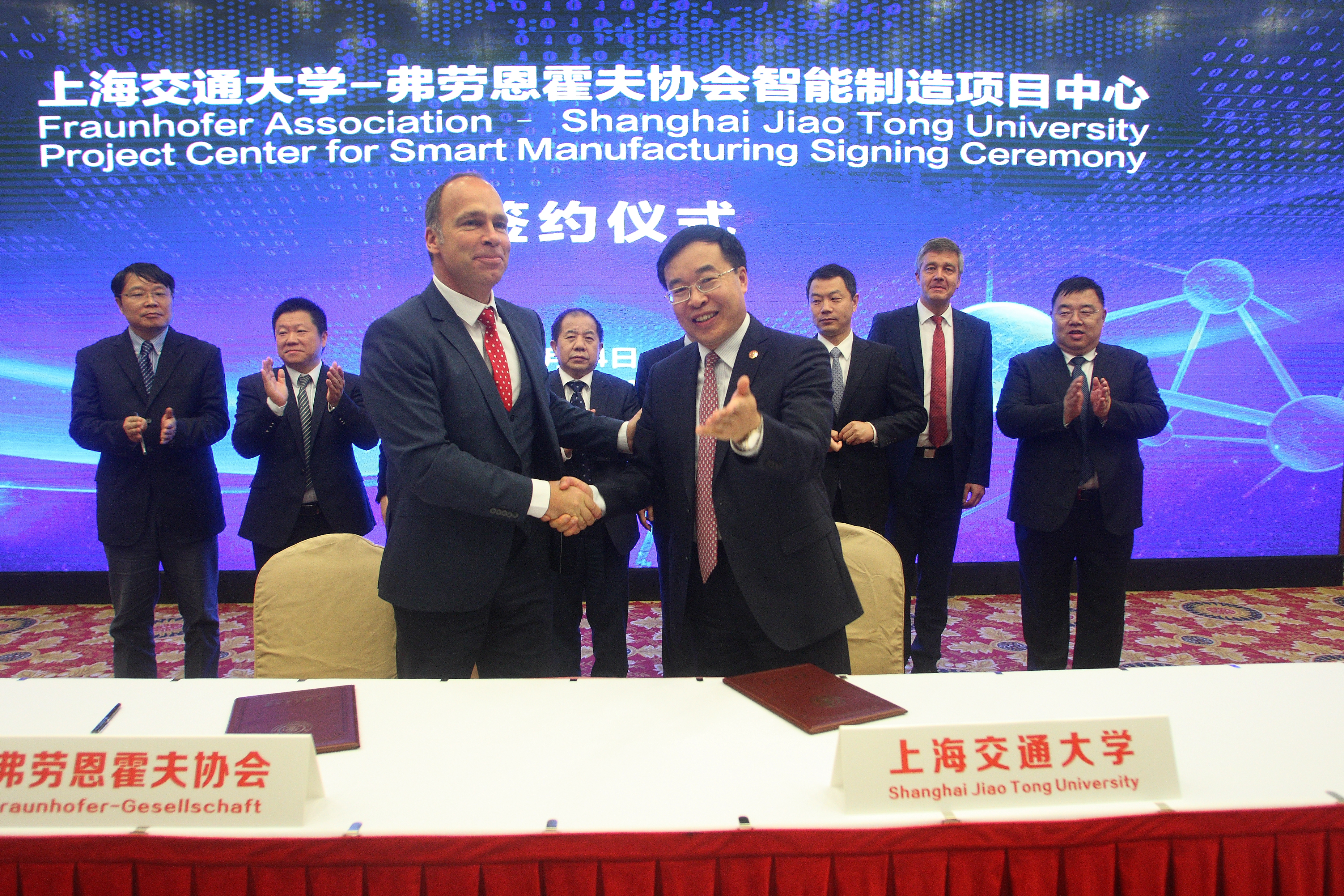

In Shanghai/Lingang, one of China’s leading science and technology regions, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA has undersigned a Memorandum of Understanding with Shanghai Jiao Tong University (SJTU), initially set to run for five years. The aim of the cooperation at the so-called “Project Center for Smart Manufacturing” is to implement projects in the research field of digital transformation in collaboration with industrial partners. The scheme’s signing ceremony was held on the 14th of October.

The Chinese government wants to support the cooperation with 10 million euros over the first five years. Besides office areas and seminar rooms, there are also plans for laboratories and experimental areas equipped with a suitable IT and hardware infrastructure. These are intended to function as a source of ideas and inspiration, in short as an innovative think tank. The knowledge gained will be imparted both to German as well as Chinese companies located in China. In the long term, the plan is for over 40 scientists from diverse professions to work at the project center.

Professor Thomas Bauernhansl, Institute Director of Fraunhofer IPA, sees great potential in the cooperation: “Already today, intelligent machines, tools and components, as well as orders, interact in networked value systems practically in realtime. Via IT components, smart objects collect data from production, engineering, coordination and management processes, enabling them to influence physical processes. Industry’s future lies in these so-called cyberphysical manufacturing systems. Industrie 4.0 is not a national but rather an international topic. What we need is international cooperation, standardization and access to the right markets. In this regard, China is a highly important partner”.

A common understanding of Industrie 4.0

Michael Lickefett, Head of Department of Factory Planning and Production Management, who is responsible for the content of the project center as far as Fraunhofer IPA is concerned, adds: “What is known in Germany under the name of Industrie 4.0 is called “Made in China 2025” there. In addition to classical topics, for example factory planning and process optimization, the main aim is to work on subjects such as artificial intelligence and their application in the fields of robotics, machine vision and language processing. As an applied research institute, we offer excellent conditions which can be ideally combined with the pioneering spirit of the Chinese”. For Lickefett, who has been keeping an eye on scientific developments in China for some time now, projects which vary too much from one another are pooled under the term Industrie 4.0. A positive effect of the roadmap drafted with the project center is therefore also educational work in the sense of a common understanding.

Stepping up the presence in the Far East

In addition, the Fraunhofer-Gesellschaft has a subsidiary in Singapore, as well as further so-called Fraunhofer Representative Offices in China, India, Indonesia, Japan and Korea. These evaluate and exploit the Asian market for the various Fraunhofer institutes and their German partners from industry to form a bridge with local Asian companies. A Fraunhofer Senior Advisor in Malaysia also supports activities on site.